Carrito de compras

Selección de distribuidor

Selecciona el distribuidor que deseas usar para tu carrito de compras.

Distribuidor

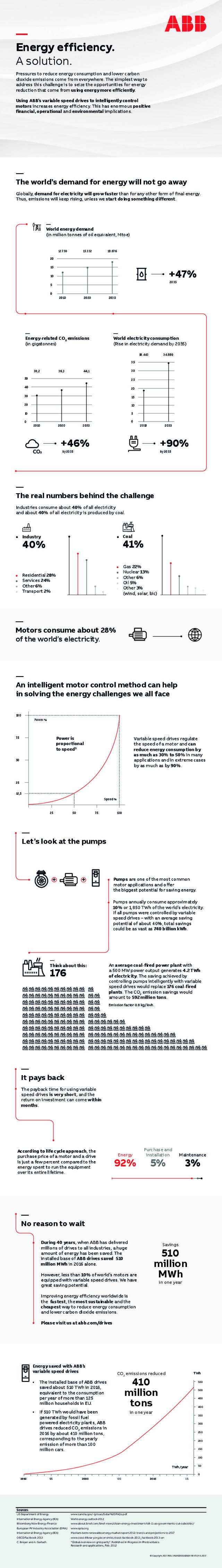

Energy efficiency. A solution

Pressures to reduce energy consumption and lower carbon dioxide emissions come from everywhere. The simplest way to address this challenge is to seize the opportunities for energy reduction that come from using energy more efficiently.

— Energy efficiency. A solution. Pressures to reduce energy consumption and lower carbon dioxide emissions come from everywhere. The simplest way to address this challenge is to seize the opportunities for energy reduction that come from using energy more efficiently. Using ABB’s variable speed drives to intelligently control motors increases energy efficiency. This has enormous positive financial, operational and environmental implications. — The world’s demand for energy will not go away Globally, demand for electricity will grow faster than for any other form of final energy. Thus, emissions will keep rising, unless we start doing something different. — World energy demand (in million tonnes of oil equivalent, Mtoe) — World electricity consumption (Rise in electricity demand by 2035) by 2035 by 2035 +90% 2035 +47% +46% 0 5 10 15 20 12.730 15.332 18.676 2010 2020 2035 10 0 20 30 40 50 30,2 36,3 44,1 2010 2020 2035 15 10 5 0 20 25 30 35 18.443 34.889 2010 2035 — Energy-related CO 2 emissions (in gigatonnes) — The real numbers behind the challenge Industries consume about 40% of all electricity and about 40% of all electricity is produced by coal. Industry 40% Coal 41% Residential 28% Services 24% Other 6% Transport 2% Gas 22% Nuclear 13% Other 6% Oil 5% Other 3% (wind, solar, bic) — Motors consume about 28% of the world’s electricity. — An intelligent motor control method can help in solving the energy challenges we all face Variable speed drives regulate the speed of a motor and can reduce energy consumption by as much as 30% to 50% in many applications and in extreme cases by as much as by 90%. Power is proportional to speed 3 Speed % Power % 12,5 25 25 50 75 100 50 75 100 — Let’s look at the pumps Pumps are one of the most common motor applications and offer the biggest potential for saving energy. + + Pumps annually consume approximately 10% or 1,850 TWh of the world’s electricity. If all pumps were controlled by variable speed drives – with an average saving potential of about 40%, total savings could be as vast as 740 billion kWh. — It pays back The payback time for using variable speed drives is very short, and the return on investment can come within months. According to life cycle approach, the purchase price of a motor and a drive is just a few percent compared to the energy spent to run the equipment over its entire lifetime. Energy saved with ABB’s variable speed drives • The installed base of ABB drives saved about 510 TWh in 2016, equivalent to the consumption per year of more than 125 million households in EU. • If 510 TWh would have been generated by fossil fuel powered electricity plants, ABB drives reduced CO 2 emissions in 2016 by about 410 million tons, corresponding to the yearly emission of more than 100 million cars. Sources: US Department of Energy www.sandia.gov/~jytsao/Solar%20FAQs.pdf International Energy Agency (IEA) World energy outlook 2012 Bloomberg New Energy Finance www.about.bnef.com/bnef-news/clean-energy-investment-fell-11-as-governments-cut-subsidies/ European PV Industry Association (EPIA) www.epia.org International Energy Agency (IEA) Medium-term renewable energy market report 2012: trends and projections to 2017 OECD Factbook 2013 www.oecd-ilibrary.org/economics/oecd-factbook-2013_factbook-2013-en C. Breyer and A. Gerlach. “Global overview on grid parity”. Published in Progress in Photovoltaics: Research and applications, Feb. 2012 Energy 92% Purchase and installation 5% CO 2 emissions reduced 410 million tons in one year Maintenance 3% An average coal-fired power plant with a 500 MW power output generates 4.2 TWh of electricity. The saving achieved by controlling pumps intelligently with variable speed drives would replace 176 coal-fired plants. The CO 2 emission savings would amount to 592 million tons. Emission factor 0.8 kg/kWh. — Think about this: 176 CO 2 — No reason to wait During 40 years, when ABB has delivered millions of drives to all industries, a huge amount of energy has been saved. The installed base of ABB drives saved 510 million MWh in 2016 alone. However, less than 10% of world’s motors are equipped with variable speed drives. We have great saving potential. Improving energy efficiency worldwide is the fastest, the most sustainable and the cheapest way to reduce energy consumption and lower carbon dioxide emissions. Please visit us at abb.com/drives Savings 510 million MWh in one year © Copyright 2017 ABB. 3AUA0000182864 REV B 24.5.2017 1992 95 05 2010 15 2000 0 50 100 150 200 250 300 350 400 450 500 550 TWh TWh/year